Machine Generated Data

Tags

Amazon

created on 2019-05-31

| Poster | 68.9 | |

|

| ||

| Advertisement | 68.9 | |

|

| ||

| Ceiling Fan | 65.8 | |

|

| ||

| Appliance | 65.8 | |

|

| ||

| Text | 61.3 | |

|

| ||

| Art | 61.1 | |

|

| ||

| Vehicle | 58.5 | |

|

| ||

| Transportation | 58.5 | |

|

| ||

| Airplane | 58.5 | |

|

| ||

| Aircraft | 58.5 | |

|

| ||

Clarifai

created on 2019-05-31

Imagga

created on 2019-05-31

| design | 23.2 | |

|

| ||

| card | 21.1 | |

|

| ||

| business | 19.4 | |

|

| ||

| paper | 18.5 | |

|

| ||

| sign | 18 | |

|

| ||

| symbol | 17.5 | |

|

| ||

| silhouette | 16.6 | |

|

| ||

| drawing | 16.5 | |

|

| ||

| retro | 14.7 | |

|

| ||

| graphic | 13.9 | |

|

| ||

| art | 13.6 | |

|

| ||

| banner | 12.9 | |

|

| ||

| man | 12.8 | |

|

| ||

| bookmark | 12.5 | |

|

| ||

| male | 12.1 | |

|

| ||

| blank | 12 | |

|

| ||

| set | 11.9 | |

|

| ||

| template | 11.9 | |

|

| ||

| cartoon | 11.6 | |

|

| ||

| black | 11.4 | |

|

| ||

| office | 11.2 | |

|

| ||

| modern | 11.2 | |

|

| ||

| celebration | 11.2 | |

|

| ||

| grunge | 11.1 | |

|

| ||

| letter | 11 | |

|

| ||

| device | 10.8 | |

|

| ||

| collection | 10.8 | |

|

| ||

| vintage | 10.7 | |

|

| ||

| style | 10.4 | |

|

| ||

| icon | 10.3 | |

|

| ||

| professional | 10.1 | |

|

| ||

| message | 10 | |

|

| ||

| old | 9.8 | |

|

| ||

| text | 9.6 | |

|

| ||

| pattern | 9.6 | |

|

| ||

| menu | 9.5 | |

|

| ||

| money | 9.4 | |

|

| ||

| decoration | 9.3 | |

|

| ||

| finance | 9.3 | |

|

| ||

| note | 9.2 | |

|

| ||

| stamp | 9 | |

|

| ||

| 8.6 | ||

|

| ||

| sketch | 8.5 | |

|

| ||

| decorative | 8.3 | |

|

| ||

| greeting | 8.3 | |

|

| ||

| element | 8.3 | |

|

| ||

| people | 7.8 | |

|

| ||

| product | 7.8 | |

|

| ||

| bag | 7.7 | |

|

| ||

| communication | 7.6 | |

|

| ||

| book jacket | 7.5 | |

|

| ||

| box | 7.5 | |

|

| ||

| fun | 7.5 | |

|

| ||

| holding | 7.4 | |

|

| ||

| page | 7.4 | |

|

| ||

| sport | 7.4 | |

|

| ||

| coffee | 7.4 | |

|

| ||

| funny | 7.3 | |

|

| ||

| holiday | 7.2 | |

|

| ||

| shopping | 7.2 | |

|

| ||

| creation | 7.1 | |

|

| ||

| notebook | 7 | |

|

| ||

Google

created on 2019-05-31

| Text | 85.2 | |

|

| ||

| Font | 80.4 | |

|

| ||

| Room | 71.4 | |

|

| ||

| Poster | 69 | |

|

| ||

| Illustration | 62.3 | |

|

| ||

| Art | 58.1 | |

|

| ||

| Black-and-white | 56.4 | |

|

| ||

| Shoe | 52.1 | |

|

| ||

| Graphic design | 51.5 | |

|

| ||

Color Analysis

Feature analysis

Amazon

Poster

Ceiling Fan

Airplane

Categories

Imagga

| paintings art | 89.7% | |

|

| ||

| text visuals | 7.6% | |

|

| ||

| streetview architecture | 1.1% | |

|

| ||

Captions

Microsoft

created on 2019-05-31

| a close up of text on a white surface | 50.7% | |

|

| ||

| a close up of text on a white background | 50.6% | |

|

| ||

| close up of text on a white surface | 46.2% | |

|

| ||

Text analysis

Amazon

together

ONE-WAY

edge

fourth

CORNER

tical

through

assembly

three

POST

consist

the assembly three parts first nested together

nested

trical

the

eftect

show

inserted

parts

THREE

trical edge to eftect any

then

which

FOUR-WAY

home

stamped

and

first

above

driven

the fourth then driven home hammer. The

tical and joints consist stamped

means

to

The

WAY

wedaes

any

are

framing.

die

parts the and framing. die wedaes which are shop inserted

hammer.

diaarams above show how. means

Wedge

TWO. WAY

diaarams

joints

TWO.

how.

shop

0

Wedge

connectors,

spaced

3

apart

all

ver-

tical

joints

consist

of

steel

wedges

which

inserted

into

FOUR-WAY

THREE-WAY

Two.wAY

CORNER

the

three

fourth

is

driven

home

with

hammer

The

above

show

an

possible

effect

desired

com

bination,

whereby

elements

interchangeable

and

are

lush

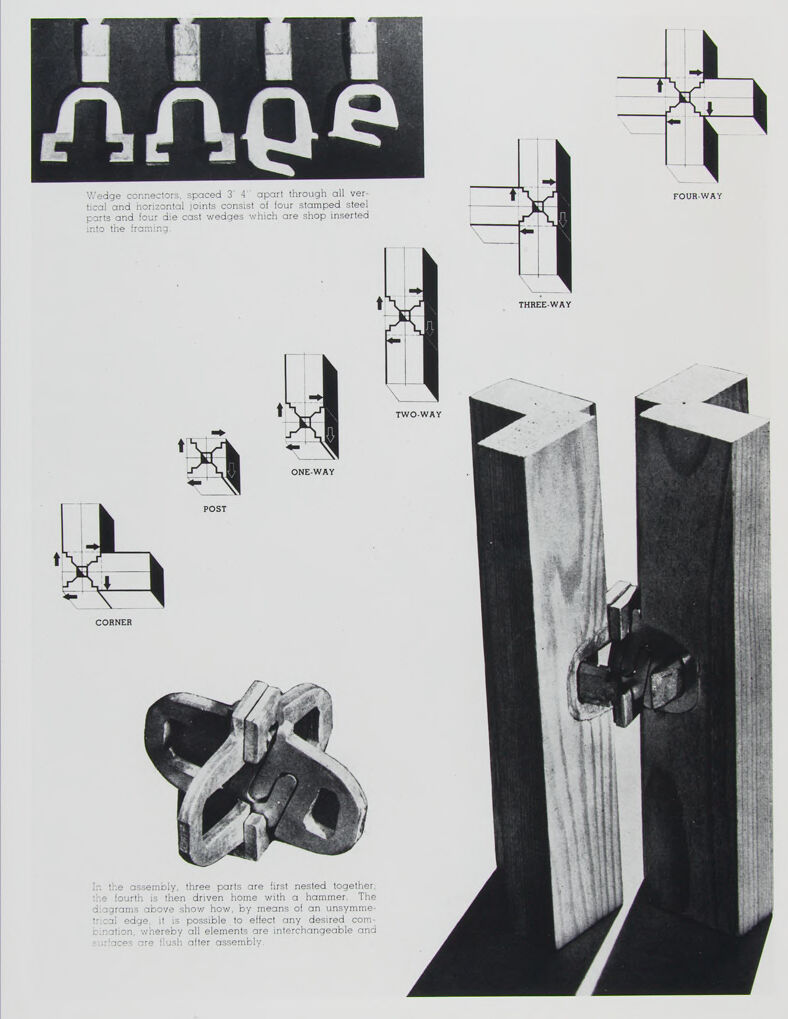

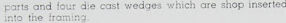

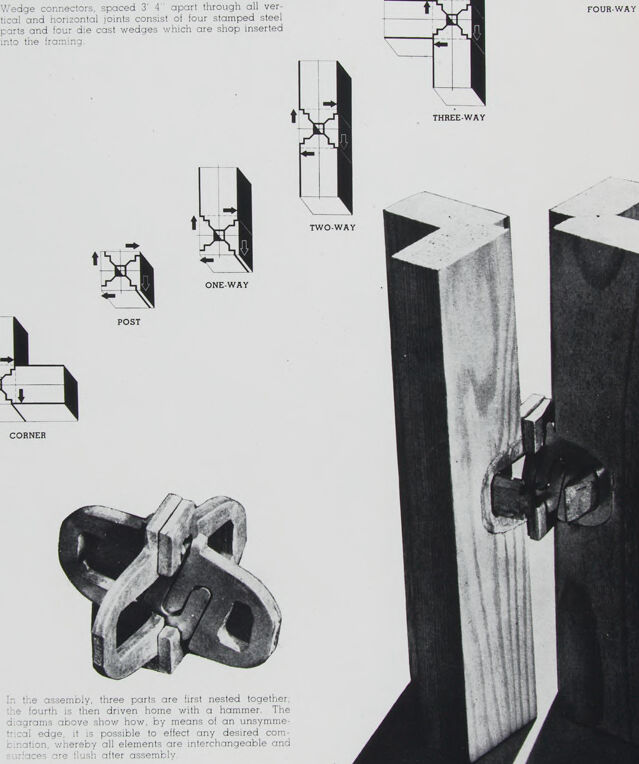

Wedge connectors, spaced 3 4" apart through all ver-

tical and horizontal joints consist of four stamped steel

parts and four die cast wedges which are shop inserted

into the framing

FOUR-WAY

THREE-WAY

Two.wAY

ONE-WAY

POST

CORNER

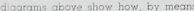

in the assembly, three parts are first nested together

the fourth is then driven home with a hammer The

diagrams above show how, by means of an unsymme-

trical edge, it is possible to effect any desired com

bination, whereby all elements are interchangeable and

surlaces are lush after assembly

4"

through

horizontal

four

stamped

parts

die

cast

shop

framing

ONE-WAY

POST

in

assembly,

first

nested

together

then

a

diagrams

how,

by

means

unsymme-

trical

edge,

it

to

any

surlaces

after

assembly