Machine Generated Data

Tags

Color Analysis

Feature analysis

Amazon

Clarifai

Clarifai

| Book | 88.2% | |

Categories

Imagga

created on 2022-05-28

| text visuals | 96.8% | |

| streetview architecture | 3% | |

Captions

Microsoft

created by unknown on 2022-05-28

| a close up of a sign | 81.9% | |

| a close up of text on a blue surface | 75.6% | |

| a blue and white text | 75.5% | |

Clarifai

No captions written

Salesforce

Created by general-english-image-caption-blip on 2025-05-21

a photograph of a blueprinted blueprint of a blueprinted diagram of a computer

Created by general-english-image-caption-blip-2 on 2025-06-29

a blueprint for a refrigerator with instructions on how to use it

OpenAI GPT

Created by gpt-4o-2024-05-13 on 2024-12-29

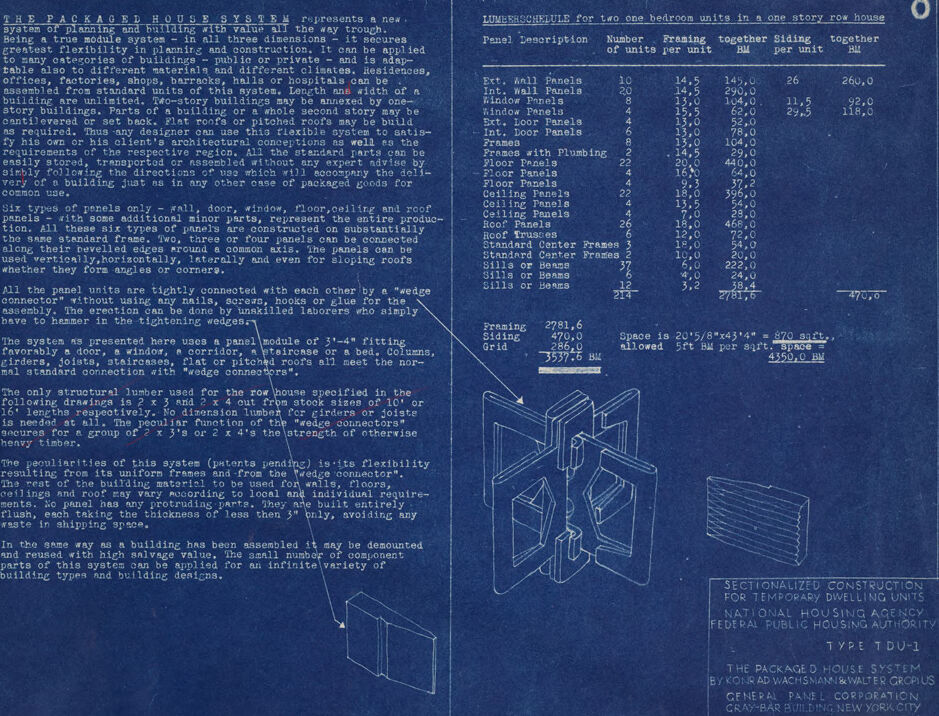

This image appears to be a blueprint of "The Packaged House System" developed for temporary dwelling units under a project supported by the National Housing Agency and Federal Public Housing Authority. The blueprint, labeled "Type TDU-1," was designed by Konrad Wachsmann and Walter Gropius and produced by General Panel Corporation in New York City.

The blueprint includes several sections:

Textual Description: The left portion contains a detailed description of "The Packaged House System," discussing the planning flexibility, modular design, and construction advantages of the system. It describes the use of six types of panels (wall, floor, window, door, and others) in varied configurations to create numerous building types. The panels are connected using "wedge connectors," which allow for easy assembly and flexibility in construction.

Lumber Schedule: The upper right part lists the lumber requirements for constructing two one-bedroom units in a one-story row house. It includes the panel descriptions (e.g., ext. wall panels, int. wall panels, window panels), quantity needed, and the amount of lumber required for framing, siding, and other components.

Material Quantities: The bottom right corner includes total numbers for framing, siding, grid, and total board measurement (BM), along with an area recommendation of 870 sq. ft. and spacing values.

Diagram: An isometric diagram is shown near the lower right side, which visually demonstrates how the panels interconnect, showcasing the modularity and ease of assembly of the system.

The blueprint highlights the innovative approach to creating affordable and versatile housing units with an emphasis on modular panels and simplified construction techniques.

Created by gpt-4 on 2024-12-05

This image is a blueprint of "The Packaged House System" designed by Konrad Wachsmann and Walter Gropius for the General Panel Corporation. The blueprint features text on the left side, explaining the concept and advantages of the system, such as its flexibility, standardized components, and ease of assembly. The text is written in a typewriter-like font and is fairly dense, covering concepts like the types of panels, assembly methods, and versatility of the system.

On the right side of the blueprint, there's a table titled "Lumberschedule" for one-bedroom units in a one-story row house. The table lists components like exterior wall panels, window panels, and various framing elements with quantities, framing sizes, and the total lumber measurements needed. Below this table is a mathematical calculation of the total lumber required.

Additionally, there are three schematic illustrations: one in the upper right corner and two more prominent ones beneath it. The upper illustration appears to be a floor plan, while the two larger ones depict a three-dimensional view of the house units. The illustrations include annotations with measurements and details of the construction.

The blueprint appears to be on typical blue background with white lines and text, characteristic of architectural blueprints of the past. The document conveys information about a modular housing system, reflecting an innovative approach to prefabricated housing design. The header and footer contain additional information about the creators and the corporation, as well as the designation of the house type, which is "T-DU-1".

Anthropic Claude

Created by us.anthropic.claude-3-5-sonnet-20241022-v2:0 on 2025-06-25

This appears to be a technical blueprint or architectural document from the National Housing Agency/Federal Public Housing Authority detailing "The Packaged House System." The image shows specifications and details for a modular housing construction system, including a detailed text description of the system, a bill of materials or parts list on the right side, and technical drawings showing how different panels and components connect together.

The document describes a flexible building system using standardized panels that can be assembled in various configurations. There's a detailed breakdown of panel types (wall, door, window, floor, ceiling and roof panels) and their dimensions, along with a section showing construction details through an isometric drawing of how the panels connect.

The blueprint appears to be labeled as "Type T DU-1" and includes information about "Sectionalized Construction for Temporary Dwelling Units." The document seems to be from the General Panel Corporation located in New York City.

The blue background suggests this is likely a cyanotype or blueprint reproduction, which was a common architectural documentation method of the era.

Created by claude-3-5-sonnet-20241022 on 2024-12-26

This is a technical blueprint or architectural drawing from the "Packaged House System" created for the National Housing Agency/Federal Public Housing Authority. The document appears to be a blueprint detailing a modular construction system, featuring both written specifications and technical drawings.

The left side contains detailed text explaining the system's features and assembly process, while the right side shows a materials list/schedule for two one-bedroom units in a one-story row house. There's also an isometric drawing showing how different panels and components connect together.

The document describes a modular building system using six types of panels (wall, door, window, floor, ceiling, and roof panels) that can be assembled using "wedge connectors" without requiring skilled labor. The system was designed to be flexible and adaptable for various building types.

At the bottom right, there's a technical drawing showing sectional construction details, and the blueprint appears to be labeled as "TYPE T DU-1". The drawing is credited to the General Panel Corporation located in Gray-Bar Building, New York City.

This appears to be an innovative approach to standardized, modular construction from what was likely the mid-20th century, aimed at creating efficient and flexible housing solutions.

Created by claude-3-haiku-20240307 on 2024-12-05

This image appears to be a technical drawing or blueprint for a modular housing system called the "Packaged House System". The drawing provides a detailed description of the system, including information about the panel units, their dimensions, and how they can be assembled into a one-story row house.

The blueprint highlights the flexibility and versatility of this modular housing system, noting its ability to be easily disassembled and reassembled for various building designs. It also mentions the system's use of "wedge connectors" to tightly connect the panel units.

The image also includes a section description, indicating that this is a "Sectional Elevation Construction for Temporary Dwelling Units" designed by the National Housing Agency, Federal Public Housing Authority.

Overall, this blueprint seems to showcase an innovative approach to prefabricated and modular housing, prioritizing efficiency, flexibility, and customization in the design and construction of these residential units.

Meta Llama

Created by us.meta.llama3-2-90b-instruct-v1:0 on 2024-12-23

The image presents a technical document titled "THE PACKAGE HOUSE SYSTEM," which outlines the design and construction of a modular housing system. The document is divided into two sections: a text section on the left and a diagram section on the right.

Text Section:

- The text section provides an overview of the system's features, including its flexibility in planning and construction, adaptability to various building types, and ability to be assembled from standard units.

- It highlights the system's use of a panel module of 3'-4" fitting favorably in a window, corridor, staircase, or bed, columns, girders, joists, and floors, with all panels connected by a "wedge connector" without using nails, screws, hooks, or glue.

- The text also mentions that the system can be used for various building types and designs, including residential, commercial, and industrial buildings.

Diagram Section:

- The diagram section shows a detailed illustration of the system's components, including the panel module, wedge connector, and framing grid.

- The diagram highlights the system's flexibility and versatility, with arrows indicating how the panels can be connected and arranged to form different building configurations.

- The diagram also includes a key that explains the different components and their functions.

Overall:

- The image provides a comprehensive overview of the Package House System, highlighting its innovative design and construction features.

- The document suggests that the system offers a flexible and efficient solution for building construction, with the potential to reduce costs and improve quality.

- The image is likely intended for architects, engineers, and builders who are interested in learning more about the system and its applications.

Created by us.meta.llama3-2-11b-instruct-v1:0 on 2024-12-05

The image presents a detailed blueprint for a two-bedroom unit within a one-story row house, titled "THE PACKAGED HOUSE SYSTEM." The blueprint is divided into two sections: the left side features a description of the system and its components, while the right side displays a table summarizing the materials required for the construction of two units.

Description of the System and Components

- The system is designed to be flexible and adaptable to various building types, including public or private residences, offices, factories, shops, barracks, halls, or hospitals.

- It consists of six types of panels: wall, door, window, floor, ceiling, and roof panels.

- Each panel type has multiple minor parts, which are constructed on a standard frame.

- The panels can be connected along their parallel sides around a common axis, allowing for vertical, horizontal, or sloping roofs.

- All panel units are tightly connected with each other by a "wedge connector" without using nails, screws, hooks, or glue.

- The system is presented as a panel module of 5'-4" fitting favorably a door, window, a corridor, a staircase, or a bed, rooms, girders, joists, staircases, slats, or pitched roofs all meet the normal standard connection with "wedge connectors."

- The only structural lumber used for the row house specified in the following drawings is 2 x 3 and 2 x 4 from stock sizes of 10" or 16" lengths respectively.

- No dimension lumber for girders or joists is needed at all.

- The peculiar function of the "wedge connectors" secures for the group of 2 x 3's or 2 x 4's the strength of otherwise heavy timber.

- The peculiarities of this system (patents pending) is its flexibility resulting from its uniform frames and one wedge connector.

- The rest of the building material to be used for walls, floors, ceilings and roof say vary according to local and individual requirements.

- No panel has any protruding parts, they are built uniformly flush, each taking the thickness of less than 1/2", only, avoiding any waste in shipping space.

- In the same way as a building has been assembled it may be dismantled and reused with high salvage value.

- The small number of component parts of this system can be applied for an infinite variety of building types and building designs.

Table Summarizing Materials Required

| Panel Description | Number of Units per Unit | Framing | Siding | Together |

|---|---|---|---|---|

| Ext. Wall Panels | 10 | 14,500 | 26 | 260,0 |

| Int. Wall Panels | 20 | 14,500 | 290,0 | 116,0 |

| Window Panels | 8 | 14,500 | 11,5 | 92,0 |

| Dr. Door Panels | 4 | 14,500 | 29,3 | 118,0 |

| Int. Door Panels | 6 | 14,500 | 78,0 | - |

| Frames | 8 | 14,500 | 14,0 | 112,0 |

| Frame with Plumbing | 4 | 14,500 | 44,0 | 64,0 |

| Floor Panels | 22 | 14,500 | 64,0 | 64,0 |

| Ceiling Panels | 4 | 14,500 | 36,2 | 36,2 |

| Roof Panels | 2 | 14,500 | 28,0 | 28,0 |

| Roof Trusses | 2 | 14,500 | 64,0 | 64,0 |

| Standard Center Frames | 3 | 14,500 | 24,0 | 24,0 |

| Sills or Headers | 7 | 14,500 | 22,7 | 22,7 |

| Sills or Headers | 12 | 14,500 | 18,4 | 18,4 |

| Framing | 2781,6 | 470,0 | - | - |

| Siding | 266,0 | - | 3537,6 | - |

| Space is 2015/9"x43'4" = 870 sqft. | - | - | - | - |

Summary of the Blueprint

The blueprint provides a comprehensive overview of the packaged house system, including its components, materials required, and construction details. The system is designed to be flexible and adaptable to various building types, and its unique features, such as the use of wedge connectors and the absence of dimension lumber for girders or joists, make it an efficient and cost-effective solution for building construction.

Amazon Nova

Created by amazon.nova-lite-v1:0 on 2025-02-28

This image is a technical drawing or blueprint for the Packaged House System, a modular construction system designed for residential buildings. The image consists of two main sections: text on the left and technical drawings on the right.

The text on the left provides an overview of the Packaged House System, highlighting its features and benefits. It mentions that the system offers flexibility in planning and construction, can be applied to various types of buildings, and is suitable for both public and private sectors. The system is described as a true module system, with panels of different dimensions that can be assembled from standard units. The text also notes that the system is designed to meet the architectural requirements of the respective region and can be easily transported and assembled without expert advice.

The technical drawings on the right illustrate the components and assembly process of the Packaged House System. They include diagrams of the various panel types, such as wall, door, window, floor, ceiling, and roof panels, along with their dimensions and quantities. The drawings also show the connections between the panels, emphasizing the use of "wedge connectors" for a tight and secure assembly.

The bottom section of the image provides additional details about the system's construction, including the use of structural lumber, the space requirements for different components, and the potential for reuse and reassembly of the panels. The image also includes a reference to the National Housing Agency Federal Public Housing Authority and the Packaged House System's Type TD-1 designation.

Overall, the image serves as a technical guide for the Packaged House System, providing both textual and visual information to help builders and architects understand the system's components, assembly process, and potential applications.

Created by amazon.nova-pro-v1:0 on 2025-02-28

The image is a blue architectural blueprint, possibly from the mid-20th century, featuring a detailed plan for a modular house system called "The Packaged House System." The blueprint is divided into sections, including a descriptive text, a lumber schedule, and a diagram of the house's modular components.

The descriptive text explains the system's flexibility, ease of assembly, and adaptability to various building types, such as offices, factories, shops, barracks, and hospitals. It highlights the use of standard units, uniform frames, and "wedge connectors" for joining panels without nails, screws, or glue. The system allows for the construction of one- or two-story buildings with varying dimensions.

The lumber schedule lists the quantities and dimensions of different types of panels (wall, window, door, floor, ceiling, and roof) required for two one-bedroom units in a one-story row house. It includes framing, siding, and other materials needed for the construction.

The diagram on the right side of the blueprint illustrates the modular components of the house, including the panel module, framing, and the arrangement of the wedge connectors. The diagram shows how the panels are connected and the overall structure of the house.

The blueprint also includes a section titled "Sectionalized Construction for Temporary Dwelling Units," indicating that the system can be used for temporary housing projects. The bottom of the blueprint lists the creators of the system, including Korrad Wachsmann and Walter Gropius, and the General Panel Corporation as the manufacturer.

Google Gemini

Created by gemini-2.0-flash on 2025-04-27

Here is a description of the image:

The image is an architectural blueprint of a sectionalized construction system for temporary dwelling units, labeled as Type TDU-1. It features the "Packaged House System" developed by Konrad Wachsmann & Walter Gropius, from General Panel Corporation in New York City. The blueprint is mainly text-based and technical drawings on a blue background.

Key elements include:

Text Description:

- Detailed description of the Packaged House System, emphasizing its modularity, adaptability, and ease of assembly without specialized skills or tools. It highlights the use of a "wedge connector" for joining panels.

- The system uses a panel module of 3-4 inches, fitting doors, windows, corridors, staircases, etc. Columns, girders, and roofs meet the standard connection with "wedge connectors".

- Mention of structural lumber size and the flexibility resulting from uniform frames and wedge connectors.

Lumber Schedule:

- Table titled "LUMBERSCHELULE for two one bedroom units in a one story row house."

- The table lists panel descriptions (e.g., Ext. Wall Panels, Int. Wall Panels, Window Panels), the number of units per unit, framing together BM per unit, and siding together BM.

Technical Drawings:

- Isometric illustrations of the wedge connectors and stacked panels

- Arrow points from the word "Grid" to the drawing

Calculations:

- Calculations related to spacing and BM (Board Measure)

- "Space is 20'5/8"x43'4" = 870 sqrt., allowed 5ft BM per sqrt. space = 4350,0 BM"

Header:

- A header reading "SECTIONALIZED CONSTRUCTION FOR TEMPORARY DWELLING UNITS" and the names of the National Housing Agency and Federal Public Housing Authority.

The overall layout of the blueprint conveys the technical and systematic approach of the Packaged House System, with its modular design and prefabricated components for efficient construction of temporary dwellings.

Created by gemini-2.0-flash-lite on 2025-04-27

This image is a technical document, likely a blueprint or an architectural plan for a building system called "The Packaged House System." Here's a breakdown:

Content:

- Descriptive Text: The main body of the image provides a detailed description of the "Packaged House System." It highlights features like its flexibility, modular design, ease of construction, and use of standard components. The system aims to be adaptable to various building types and climates.

- Lumber Schedule: There's a "Lumber Schedule" for two one-bedroom units in a one-story row house. This table details the different panel types (e.g., wall panels, window panels, floor panels) and lists the number of units, the framing volume, siding volume, and total volume.

- Diagrams: The image includes a diagram showing a 3D representation of the "wedge connector" which is mentioned throughout the descriptions and is crucial for connecting the building's components.

- Dimensions and Calculations: Some calculations are provided, such as the total space of the building, and volume calculations.

- Identification: The document is identified as "TYPE TDU-1" and is associated with the "National Housing Agency, Federal Public Housing Authority." It also identifies the designers: Konrad Wachsmann & Walter Gropius, with the General Panel Corporation.

- Design/Layout: The overall layout is characteristic of technical drawings, with clear labeling, organized data tables, and the use of blue or black ink, which are all indicators of a plan or blueprint.

Overall Impression:

The image is a technical document intended to explain and promote the "Packaged House System." It emphasizes the ease of construction, versatility, and cost-effectiveness of the system. The focus is on the modular design and the use of pre-fabricated components.

Mistral Pixtral

Created by us.mistral.pixtral-large-2502-v1:0 on 2025-04-27

The image is a blueprint document for a "Packaged House System," detailing a modular system for planning and constructing buildings. Here are the key points summarized from the blueprint:

System Overview:

- The Packaged House System is a modular system that allows for flexibility in building design and construction.

- It is adaptable to various building types, materials, and climates.

- The system uses standard units that can be assembled in multiple ways, making it easy to modify or expand buildings.

Components:

- The system includes various types of panels such as wall panels, floor panels, ceiling panels, and roof panels.

- Additional minor parts like frames, sills, and trusses are also part of the system.

- All components are constructed with a common axis, allowing for easy assembly in vertical, horizontal, and diagonal orientations.

Assembly:

- Panels are connected using a wedge system, which allows for easy assembly and disassembly by unskilled laborers.

- The system uses a panel module of 3'-4" fitting, allowing for flexibility in design.

- Structural lumber used is either 2x3 or 2x4, with stock sizes of 10' or 12'.

Flexibility:

- The system's flexibility allows for the use of different materials for walls, floors, ceilings, and roofs.

- Buildings can be designed and assembled according to individual requirements, ensuring efficient use of space.

Specifications:

- The blueprint provides a detailed list of panel types, their quantities, framing, and siding requirements for a two-bedroom unit in a one-story row house.

- It includes specific measurements and material requirements for the construction.

Construction Standards:

- The system adheres to standards set by the National Housing Agency and the Federal Public Housing Authority.

- It is designed for temporary dwelling units, ensuring compliance with regulatory requirements.

Illustrations:

- The blueprint includes diagrams illustrating the assembly of panels and the overall structure of the building.

- It provides a visual representation of how the modular system works.

Overall, the blueprint outlines a comprehensive and flexible modular building system designed for easy assembly and adaptability to various building needs.

Qwen

Created by Qwen/Qwen2.5-VL-7B-Instruct on 2025-06-27

The image appears to be a technical blueprint or technical document for a packaged house system. The left side of the page has a large block of text that describes the "Packaged House System." It mentions that the system is designed to be a module system with great flexibility in planning and construction, applicable to various building types such as residences, offices, factories, shops, and hospitals. The text outlines the system's features, including the variety of panels and their dimensions, as well as the ease of construction and adaptability.

The right side of the page contains a detailed "Lumber Schedule" for two one-bedroom units in a one-story row house. This schedule lists various panels and components used in the construction, including exterior wall panels, interior wall panels, window panels, door panels, frames, and more, detailing the number of units per part and the total quantity. There are also sections for framing, siding, and a grid to summarize the space requirements and material amounts needed for the construction.

The bottom right corner of the page states that the system is "Sectionalized Construction for Temporary Dwelling Units" and credits the development to the National Housing Agency, Federal Public Housing Authority, General Panel Corporation, and Cray-Bar Building in New York City. The blueprint also features a diagram showing the connection of the panels and a note indicating the use of a "wedge connector" without the need for nails, screws, hooks, or glue.

Overall, the document provides a comprehensive overview of the packaged house system's components, usage, and construction details.

Created by Qwen/Qwen2.5-VL-72B-Instruct on 2025-06-27

This image shows a blueprint of a packaged house system for temporary dwellings, designed for two one-bedroom units in a one-story row house. The blueprint includes a detailed description of the system, which is a modular construction method that allows for flexibility in planning and construction. The text explains that the system uses standard units that can be assembled to create various types of buildings, including residences, offices, factories, shops, barracks, and hospitals. The system is designed to be easily stored, transported, and assembled without expert advice, similar to other packaged goods.

The blueprint also includes a lumber schedule that lists the number of units per unit for various types of panels, such as exterior wall panels, interior wall panels, window panels, interior floor panels, and ceiling panels. The schedule provides information on the framing, siding, and other materials used in the construction of the units.

Additionally, the blueprint features diagrams and illustrations of the panel units and their connections, showing how they are tightly connected using wedge connectors. The text emphasizes the simplicity of the assembly process, which can be done by unskilled laborers without the use of nails, screws, hooks, or glue.

The blueprint is titled "THE PACKAGED HOUSE SYSTEM" and is attributed to Konrad Wachsmann and Walter Gropius. It is associated with the "GENERAL PANEL CORPORATION" and the "CRAY-BAR BUILDING NEW YORK CITY." The system is designed for the "NATIONAL HOUSING AGENCY" and the "FEDERAL PUBLIC HOUSING AUTHORITY."