Machine Generated Data

Tags

Color Analysis

Feature analysis

Amazon

Clarifai

Clarifai

| Book | 79.2% | |

Categories

Imagga

created on 2019-03-25

| text visuals | 99.9% | |

Captions

Microsoft

created by unknown on 2019-03-25

| a close up of text on a white background | 87.3% | |

| a close up of text on a black background | 84% | |

| a close up of text on a white surface | 83.9% | |

Clarifai

Created by general-english-image-caption-clip on 2025-07-14

a drawing of the proposed design.

Salesforce

Created by general-english-image-caption-blip on 2025-05-03

a photograph of a drawing of a drawing of a plan for a kitchen

OpenAI GPT

Created by gpt-4o-2024-11-20 on 2025-06-07

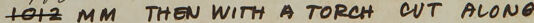

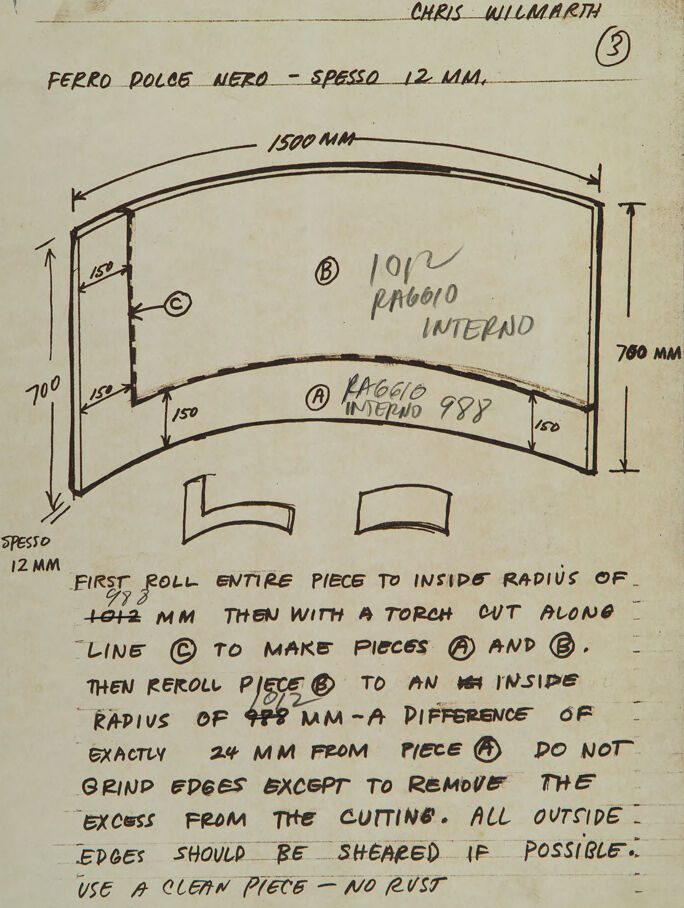

This image is a sketch or technical drawing, likely related to fabrication or metalworking. It contains measurements, annotations, and instructions in handwritten text, detailing the dimensions and process for shaping a metal piece.

Key Features of the Drawing:

Title and Material:

At the top, it reads "CHRIS WILMARTH" (possibly the designer's name). Below that, the material is stated: "FERRO DOLCE NERO - SPESSO 12 MM" (translated from Italian as "Mild black iron - thickness 12 mm").Main Diagram:

- The central shape resembles a curved rectangular arc.

- Dimensions are provided prominently:

- The arc length at the top is 1500 mm.

- The height is 700 mm.

- Thickness is noted as Spesso 12 mm (12 mm thick).

- Internal radii are labeled:

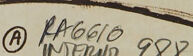

- "A" with a radius of 988 mm.

- "B" with a noted modification: "1012 RAGGIO INTERNO" (translated: "Internal Radius 1012 mm").

Smaller Shapes:

- Below the main diagram are two curved rectangular segments. These are labeled "A" and "B," corresponding to the larger shape's cut sections after processing.

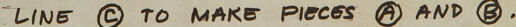

Lengthy Instructions (Bottom):

- The text provides detailed fabrication steps:

- Rolling: Roll the entire piece to an initial radius of 1012 mm.

- Cutting: Use a torch to cut along line "C" to create pieces "A" and "B."

- Re-Rolling Piece B: After cutting, roll piece "B" to achieve an inner radius of 988 mm, creating a difference of 24 mm compared to piece "A."

- Grinding and Shearing: Grind edges only to remove excess from cutting; shear outer edges if possible.

- Condition: Use a clean, rust-free piece for fabrication.

- The text provides detailed fabrication steps:

Notations and Observations:

- The handwriting is rough but clear, serving as practical notes for fabrication purposes.

- The drawing mixes diagrams and textual instructions, making it accessible for a technician or artisan familiar with these processes.

- The document appears to focus on precision and cleanliness during machining.

This sketch is technical in nature and likely pertains to custom metalwork, possibly for sculpture or structural components.

Created by gpt-4o-2024-08-06 on 2025-06-07

The image is a hand-drawn diagram and set of instructions by Chris Wilmarth for fabricating a curved metal piece. The drawing features a schematic of a curved section labeled with various dimensions and notes.

Key elements of the diagram include:

- The title at the top reads "CHRIS WILMARTH" along with the number "(3)".

- The main material is noted as "FERRO DOLCE NERO - SPESSO 12 MM," which translates from Italian as "black mild steel - thickness 12 mm."

- The drawing shows a curved piece with dimensions: 1500 mm width, 700 mm left height, and 780 mm right height.

- Internal notes indicate it has an "INTERNO RAGGIO 1012" crossed out to "RAGGIO INTERNO 978", which means "internal radius 978" in Italian.

- It shows lines and labels such as A, B, and C, pointing to various parts of the drawing.

- The instructions written below the diagram explain the process:

- Roll the entire piece to an inside radius of 978 mm.

- Cut along line C to create pieces A and B.

- Re-roll piece B to a new inside radius, which is meant to be a difference of exactly 24 mm from piece A.

- Grind the edges only to remove excess from cutting, suggesting no grinding should alter material thickness.

- All outside edges should be sheared, if possible, and a clean, rust-free piece should be used.

This appears to be a plan for fabricating a specific piece of metalwork with precision specifications.

Anthropic Claude

Created by anthropic.claude-3-haiku-20240307-v1:0 on 2025-06-12

The image appears to be a technical drawing or instructions for creating a curved piece of metal. It contains detailed measurements, dimensions, and step-by-step instructions for cutting and shaping the metal piece. The instructions mention using a torch to cut along specific lines and then re-rolling the piece to a slightly smaller inside radius. The image does not contain any human faces or identifiable individuals.

Created by us.anthropic.claude-3-opus-20240229-v1:0 on 2025-06-12

The image shows a technical drawing or blueprint with instructions for creating a "ferro dolce nero" piece, which appears to be some kind of curved metal component with specific dimensions. The instructions specify rolling the entire piece to an inside radius of 1012 mm, then using a torch to cut along a marked line to create two separate pieces. These pieces are then re-rolled to an inside radius of 988 mm.

The notes emphasize not grinding the edges except to remove excess from the cutting, and to shear the outside edges if possible. It mentions using a "clean piece" with "no rust". The drawing includes dimensions and labels for the different sections and radii of the curved piece.

Created by us.anthropic.claude-3-5-sonnet-20241022-v2:0 on 2025-06-12

This is a technical drawing or fabrication instruction sheet labeled "FERRO DOLCE NERO - SPESSO 12 MM" (which appears to be Italian for "soft black iron - 12mm thick"). The drawing shows specifications for creating curved metal pieces with specific dimensions:

- The overall width is 1500mm

- The height is 700mm

- There are measurements of 150mm marked at various points

- Two curved sections are shown, labeled A and B, with internal radii measurements (raggio interno)

The drawing includes detailed instructions at the bottom for:

- Rolling the entire piece to an inside radius of 973mm

- Cutting along line C to create pieces A and B

- Rerolling piece B to create a 24mm difference from piece A

- Instructions about not grinding edges except to remove cutting excess

- A note that outside edges should be sheared if possible

- A reminder to use clean, rust-free material

The document appears to be labeled with "CHRIS WILMARTH" at the top and marked with a "(3)", suggesting it's part of a series of technical drawings.

Meta Llama

Created by us.meta.llama3-2-90b-instruct-v1:0 on 2025-05-23

The image is a handwritten note on a piece of paper, detailing the process for cutting and shaping a piece of metal. The note is written in black ink and includes several diagrams and measurements.

Title: "FERRO DOLCE NERO - SPESSO 12 MM" (Italian for "Black Iron - Thick 12 mm")

Diagrams:

- A curved line with arrows indicating the direction of cutting

- A rectangular shape with dimensions labeled (1500 mm x 700 mm x 12 mm)

- A smaller rectangular shape with dimensions labeled (1012 mm x 988 mm x 12 mm)

Measurements:

- 1500 mm (length)

- 700 mm (width)

- 12 mm (thickness)

- 1012 mm (length of smaller rectangle)

- 988 mm (width of smaller rectangle)

Instructions:

- Cut along the curved line to create a piece of metal with a radius of 1012 mm

- Cut along the straight line to create a piece of metal with a width of 988 mm

- Roll the entire piece to an inside radius of 1012 mm

- Cut along the curved line to create a piece of metal with a radius of 1012 mm

- Roll the entire piece to an inside radius of 1012 mm

- Cut along the straight line to create a piece of metal with a width of 988 mm

Additional Notes:

- "DO NOT GRIND EDGES EXCEPT TO REMOVE THE EXCESS FROM THE CUTTING"

- "ALL OUTSIDE EDGES SHOULD BE SHEARED IF POSSIBLE"

- "USE A CLEAN PIECE - NO RUST"

Overall, the image appears to be a set of instructions for cutting and shaping a piece of metal into a specific shape, with detailed measurements and diagrams to guide the process.

Created by us.meta.llama3-2-11b-instruct-v1:0 on 2025-05-23

The image is a hand-drawn diagram of a piece of metal, with instructions on how to cut it. The diagram is drawn in black ink on a piece of paper that appears to be aged or yellowed.

- Diagram

- The diagram shows a curved piece of metal with measurements and labels.

- The metal piece has a radius of 1012 mm and a thickness of 12 mm.

- There are two lines drawn on the metal piece, one at 700 mm and another at 1500 mm.

- The diagram also includes a note that reads "FERRO POLCE NERO - SPESO 12 MM."

- Instructions

- The instructions are written in black ink below the diagram.

- They provide step-by-step guidance on how to cut the metal piece using a torch.

- The instructions include measurements and notes on how to avoid grinding edges.

- The instructions also mention that all outside edges should be sheared if possible.

- Additional Information

- The diagram and instructions appear to be handwritten by Chris Wilmarth.

- The paper has a number "3" in the top-right corner, suggesting that it may be part of a larger set of instructions or plans.

- The overall appearance of the diagram and instructions suggests that they were created for a specific project or task, possibly in a workshop or factory setting.

Overall, the image provides a detailed and informative diagram of a metal piece, along with clear instructions on how to cut it. The use of measurements and labels adds to the clarity and precision of the diagram, making it a useful tool for anyone working with metal.

Amazon Nova

Created by amazon.nova-lite-v1:0 on 2025-05-23

The image is a technical drawing or instruction sheet, likely from a manufacturing or engineering context. The drawing depicts a curved piece of material, possibly metal, with various dimensions and instructions for its processing. The text is written in a foreign language, possibly Italian, and includes terms like "FERRO POLCE NERO" and "SPESSSO 12 MM," which translate to "black thumb iron" and "thickness 12 mm," respectively. The drawing shows a curved piece with an inner radius of 1012 mm and an outer radius of 988 mm, with a thickness of 12 mm. The instructions indicate that the piece should be rolled to the inner radius of 1012 mm, then cut along a specified line to create two separate pieces, labeled "A" and "B." Piece "B" should then be rolled to an inner radius of 988 mm, creating a difference of exactly 24 mm from piece "A." The instructions also mention not grinding the edges except to remove excess from the cutting and ensuring that all outside edges are sheared if possible. The drawing includes measurements and annotations in both the foreign language and English, providing a clear guide for the manufacturing process.

Created by amazon.nova-pro-v1:0 on 2025-05-23

The image features a technical drawing and instructions for a specific task. The drawing is on a piece of paper that appears to be slightly aged or worn, as evidenced by its slightly yellowed color and some visible creases. The drawing includes a detailed illustration of a circular object with various dimensions and labels. The object seems to be a part of a mechanical or engineering design.

The drawing is labeled with several measurements in millimeters, including "1500 MM" at the top, "700 MM" on the left side, and "150 MM" at various points along the circular object. There are also labels "A," "B," and "C" indicating different sections or parts of the object.

Below the drawing, there are detailed instructions written in a cursive style. The instructions describe a process involving rolling a piece to a specific inside radius, cutting it with a torch, and then re-rolling another piece to a slightly different inside radius. The instructions emphasize not grinding the edges except to remove excess material from cutting and suggest shearing all outside edges if possible. They also mention using a clean piece without rust.

The instructions are specific and technical, indicating that this is likely a manual for a precise manufacturing or engineering process. The paper's condition suggests that it may have been used or referenced multiple times, indicating its importance in the process it describes.

Google Gemini

Created by gemini-2.0-flash-lite on 2025-04-29

The image is a technical drawing, likely a design or instruction for a metalworking project. It appears to be a handwritten blueprint on a piece of aged paper. Here's a breakdown:

Title and Dimensions:

- The top of the drawing has the text "CHRIS WILMARTH" followed by a number 3 in a circle

- "FERRO DOLCE NERO - SPESSO 12 MM." which translates to "Sweet Black Iron - Thickness 12 mm" indicating the material and its thickness.

- Dimensions: The drawing includes measurements for the main shape:

- 1500 mm (width)

- 760 mm (height)

- 150 mm (margins)

- 700 mm (height of a side)

Shape and Features:

- The main element is a curved, rectangular shape with rounded corners.

- Inside the shape, there are callouts labeled A and B, specifying the inner radius of curvature.

- There is a point C, likely representing a cutting line.

- The drawing also contains two smaller "L" shaped cutouts, perhaps representing the removed material.

Instructions:

- The writing in the lower half of the image is likely instructions or notes for fabrication. The instructions cover:

- Rolling the entire piece to an initial inside radius

- Cutting along line C

- Rerolling piece B to a different radius

- Specifying that grinding should only be done to remove excess from cutting.

- Emphasizing that edges should be sheared.

- Finally specifying a clean, rust-free piece of metal should be used.

Overall Impression:

The drawing provides a clear picture of the project with a focus on metal bending and precision. The hand-drawn nature indicates a more manual approach.

Created by gemini-2.0-flash on 2025-04-29

Here is a description of the image:

The image is a technical drawing or blueprint sketch, likely for metalwork. It is hand-drawn on what appears to be aged or textured paper. At the top, it reads "CHRIS WILMARTH" and "FERRO DOLCE NERO - SPESSO 12 MM" in bold handwriting. To the right, there's a circled number "3."

The main part of the image is a detailed drawing of a curved, rectangular shape, labeled with various measurements. "1500 MM" spans the top curve, and "760 MM" indicates the height. Additional measurements, such as "150", are marked on the sides. The main shape is labeled "C", while the bottom curve has the text "RAGGIO INTERNO 988" and the top curve has the text "1012 RAGGIO INTERNO."

Below the main drawing are two smaller, abstract shapes that look like cross-sections or cutouts. Underneath these, there's handwritten text detailing the process for creating the object. It begins with "FIRST ROLL ENTIRE PIECE TO INSIDE RADIUS OF 1012 MM..." and continues with instructions involving torch cuts, rerolling pieces, and specifying edge treatments like shearing rather than grinding. The instructions conclude with "USE A CLEAN PIECE - NO RUST."

Mistral Pixtral

Created by us.mistral.pixtral-large-2502-v1:0 on 2025-05-24

The image is a hand-drawn technical sketch with detailed instructions for fabricating a curved metal piece. Here is a detailed summary of the image:

Title and Material:

- Title: "CHRIS WILMARTH"

- Material: "FERRO DOLOCE NERO - SPESSO 12 MM" (Black mild steel - thickness 12 mm)

Dimensions and Shape:

- The overall length of the piece is 1500 mm.

- The height of the piece is 780 mm.

- The piece is divided into two sections, labeled as (A) and (B).

Section Details:

- Section (A):

- Inside radius: 988 mm

- Height: 700 mm

- Width: 150 mm

- Section (B):

- Inside radius: 1012 mm

- Height: 780 mm

- Width: 150 mm

Instructions:

- Roll the entire piece to an inside radius of 1012 mm.

- Use a torch to cut along line (C) to separate pieces (A) and (B).

- Reroll piece (B) to an inside radius of 988 mm. The difference in radius between pieces (A) and (B) should be exactly 24 mm.

- Do not grind the edges except to remove excess material from the cutting. All outside edges should be sheared if possible.

- Use a clean piece with no rust.

Additional Notes:

- The thickness of the material is specified as 12 mm.

- The sketch includes arrows and measurements to clarify the dimensions and cutting line.

- The instructions emphasize precision in rolling and cutting to achieve the desired radii and dimensions.

This sketch provides clear and precise instructions for fabricating a specific curved metal component, ensuring accuracy in the manufacturing process.

Qwen

Created by Qwen/Qwen2.5-VL-7B-Instruct on 2025-07-05

This image appears to be a hand-drawn technical sketch or diagram, likely used for manufacturing or construction purposes. It includes measurements and instructions for a metal fabrication process. Here's a breakdown of the elements:

Title and Material Specifications:

- The title at the top of the image reads "FERRO POLCE NERO - SPESSO 12 MM," which translates from Italian to "Black Steel - Thickness 12 mm." This indicates the type of metal being worked with.

- The name "CHRIS WILMARHT" is written at the top right, possibly the person who created or is responsible for the drawing.

Main Diagram:

- The main drawing depicts a curved metal piece with specific dimensions and markings. The dimensions provided are:

- Width across the top: 1500 mm

- Height: 750 mm

- Thickness: 12 mm

- There are two circles labeled with radii:

- "Raggio interno 1012" (Internal Radius 1012 mm)

- "Raggio interno 988" (Internal Radius 988 mm)

- Two smaller, rectangular sections labeled "A" and "B" are also drawn, representing pieces that are cut from the main curved piece.

- The main drawing depicts a curved metal piece with specific dimensions and markings. The dimensions provided are:

Instructions:

- The instructions at the bottom of the image provide a procedural guide on how to fabricate the piece:

- Roll the entire piece to an internal radius of 1012 mm.

- Use a torch to cut along the line marked as "C" to produce pieces "A" and "B."

- Roll the piece "B" to an internal radius of 988 mm, which is a 24 mm difference from the piece "A."

- Do not grind the edges except to remove excess material from the cutting.

- Shear all outside edges if possible.

- Ensure the piece is clean and free of rust.

- The instructions at the bottom of the image provide a procedural guide on how to fabricate the piece:

This detailed sketch and instructions seem to be part of a technical guide for fabricating a specific curved metal component, likely for a mechanical or structural application.

Created by Qwen/Qwen2.5-VL-72B-Instruct on 2025-07-05

This is a hand-drawn technical diagram and accompanying instructions, likely for a metal fabrication project. Here's a detailed description:

Diagram:

- Title: The title at the top reads "FERRO POLCE NERO - SPESSO 12 MM," indicating the material is a 12 mm thick black steel plate.

- Main Drawing:

- The drawing shows a curved steel plate with dimensions labeled.

- The overall length of the plate is 1500 mm.

- The height of the plate is 700 mm.

- There are two sections labeled as "A" and "B," with different radii:

- Section A has an internal radius of 988 mm.

- Section B has an internal radius of 1012 mm.

- There is a cut line labeled "C" that divides the plate into the two sections A and B.

- The thickness of the plate is marked as 12 mm.

Instructions:

- Rolling and Cutting:

- First, roll the entire piece to an inside radius of 1012 mm.

- Then, cut along line C to make pieces A and B.

- Re-rolling:

- Re-roll piece B to an inside radius of 988 mm, creating a difference of exactly 24 mm from piece A.

- Edge Treatment:

- Do not grind the edges except to remove the excess from the cutting.

- All outside edges should be sheared if possible.

- Material Condition:

- Use a clean piece with no rust.

Additional Notes:

- The diagram and instructions are signed "CHRIS WILMARTH" at the top right corner.

- There is a circled number "3" near the signature, possibly indicating this is part of a series of drawings or instructions.

- The overall appearance of the paper suggests it is an older document, possibly a blueprint or a workshop instruction sheet.